Ugarteburu – the original bar-turning specialists

You could call us the originals. The ones who started it all. And that’s true – but we’re so much more than that. With over 50 years of experience in the business, no-one knows the industry better than we do. And no-one does quality and service quite like us.

The Ugarteburu story

Who are we?

First established over 50 years ago, Ugarteburu S.A. is where it all began. The Group may have expanded and diversified, but here at Ugarteburu we have stayed true to our roots. In the years since we first set the gears in motion, we have kept abreast of change and invested in the latest cutting-edge technology, whilst always remaining focused on what we do best: delivering large batches of exceptionally high-quality turned parts.

What do we do?

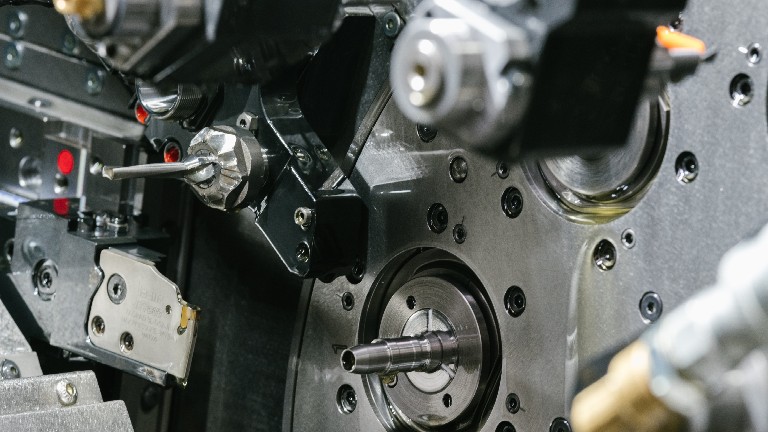

We are the original bar-turning specialists, producing consistently high-quality turned parts in large batches. We can produce parts with a bar diameter of between 5 and 40 mm thanks to our unparalleled fleet of machinery, which includes state-of-the-art multi-spindle lathes boasting CAM and CNC technology, as well as a suite of machines for cleaning parts after machining and Automatic Optical Inspection machines for final quality control checks on the parts.

Our superior quality has won us a legion of loyal customers in the automotive, electronics and gas industries, for example. Yet arguably it’s our customer service that really keeps them coming back. Our aim is to make everything as easy as possible for you – from initial consultation, concept development and product design to manufacture, shipping and aftersales support. Want to see for yourself what makes our customers fall in love with us? Get in touch!

Sectors

From micro-machined electronic components to valves and couplings – some of the biggest and best manufacturers in their industries put their faith in us to produce the all-important parts they need. Explore our core sectors to see if we can help with your machining requirements.